Manufacturing Considerations?

-

Hello,

I work for a Custom Manufacturing company, and one of our clients is utilizing an Omega2S+ as part of their assembly. I've been unsuccessful in finding information regarding manufacturing guidance. Some questions I have are...- Can the Omega2S+ run through a wash cycle? We typically use no-clean flux then run our boards through a chemistry wash.

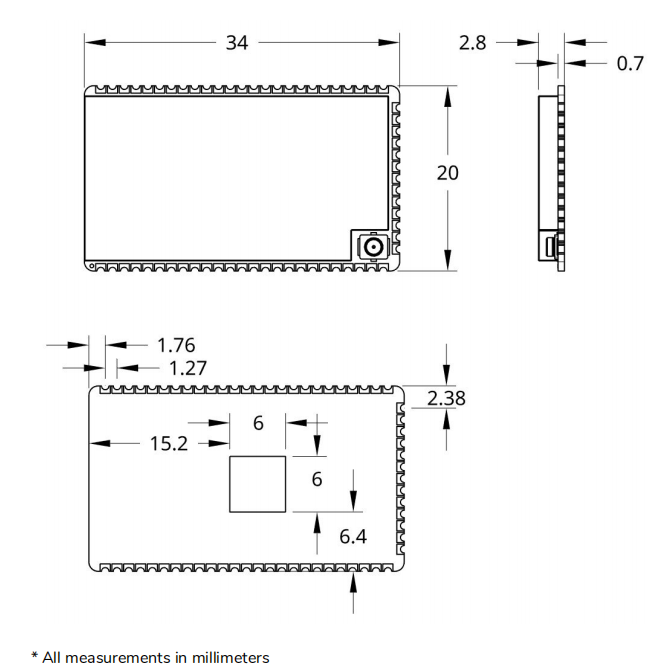

- Is there a recommended stencil thickness?

- The docs claim that the Tape and Reel are 56mm wide; however, the tape we got is 44mm. Did we get counterfeit parts? The blog post https://onion.io/omega2s-new-tape-and-reel-packaging/ says 56mm, but the picture of the actual tape and reel seems to be 44mm.

Thanks

-

Hi, I‘m onion Jeff. usually, our specifications will give some guidelines for reflow soldering, and about your manufacturing guidance, as it based on you product,it is hard for us to issue guidance.

- About the wash cycle , .

Our module is the same with the wifi module or BT module on the market. you just need to be careful that the silk screen on the label is erased by the no-clean flux . - Is there a recommended stencil thickness?

Our module Spec had the module's thickness parameter

- Tape and Reel are 56mm wide.

Sorry for the mistake, the real of the actual tape and reel is 44mm, we will change it soon and update the packaging parameter.

- About the wash cycle , .

-

Datasheet and reel blog post have been updated to reflect the correct 44mm tape width.

Sorry for the confusion!

-

Thanks for the information!