Power Omega2 from 3.7 volts?

-

@crispyoz I really, really, really wish I could up-vote this more than once! Hilarious!!!

--Bill

-

The 'Magic Smoke' is what makes it work! If you let that out, no workee end of story

-

@William-Scott @Chris-H My next project will be a magic smoke containment device with an upgrade available for smoke replacement. I imagine how many devices we could recover simply be replacing the magic smoke. Available in multiple colour variations depending on your voltage requirements!

The following project will be to replace the "bang" in DC devices connected 220V 10A power sources. I see a market here!

-

@crispyoz That is soooo funny! I was thinking along the same lines. Also thinking of inventing some sort of nano hypodermic needle that could be used to inject the magic smoke back into devices.

--Bill

-

@CAP-33 I surely hope you feel as though you've received wise counsel on your problem. I realize @crispyoz, @Chris-H and I have apparently hijacked your thread with humor. However the humor is evidence of the errors we've made and surely hope it suits you well and you have learned something valuable. Assuming you're satisfied with the effort so far, I'm going to apparently take the hijacking a bit farther with two stories in my next two posts. The first is directed at you, for sure. The second is just for laughs for everyone, but there's at least one valuable lesson there.

--Bill

-

It is unbelievable to me that next year, in May of 2021, it will be 40 years since I received my undergraduate degree in electrical engineering from Purdue University in West Lafayette, IN, USA. The Engineering Mall at Purdue is a storied place. Gus Grissom, Mercury and lost in Apollo 1 with Roger Chaffee (the A&AE building was named for Grissom). Neil Armstrong, you might have heard of him, the new A&AE and general engineering building named for him. Gene Cernan, to date the last man to walk on the moon, sat in the same seats I sat in during classes in the EE building. Pressure...pressure...pressure....we all needed to step up or go home (or go to Indiana U., ha ha ha). Prior to work I visited the Smithsonian in Washington DC and in the Air & Space Museum I saw all these mockups of satellites, all built by the Hughes Aircraft Company - awesome as just a few weeks later I would be working at Hughes. [Continues in next post]

-

After vacation I went to Chicago's O'Hare Airport, boarded a DC 10, and said a sort of goodbye to my mom, dad, two sisters, and countless other relatives and friends. I landed in Los Angeles and several days later was working as a systems engineer at Hughes Aircraft in Fullerton, CA, USA.

Here I am, a 22 year old that wants to conquer the world, and wants to do it NOW! My first boss, Jim Brennan, probably about 62, was a great guy! I learn that he had worked for Collins Radio in Santa Ana, CA and was the project engineer on the UHF radio system used to communicate from Earth to the Command Module and Lunar Module. I understand that as my dad and I are laying on our stomachs in front of the TV listening to Neil Armstrong say "This is one small step for a man..." that it was my boss that was responsible for us hearing and seeing that. I was 10 years old that day and decided i wanted to be en engineer. To me, Jim was a god, and he was my first boss.

Why did I tell you all of this, @CAP-33? In almost 40 years of engineering, I've let the magic smoke out a few times. Nahhhh......let's be honest.....a few dozen times! Or is it a couple hundred times?

Jim taught me something spectacularly important. He taught me I couldn't solve every problem simultaneously. He taught me professional engineering is methodical...it is deliberate. He taught me you can only go so fast. If you try to go faster, you actually slow down (e.g. all of the recoveries from letting the magic smoke escape). He taught me, sure we hack at things, but to do things "right" we might need to order parts and wait for them to arrive. He taught me to SLOW DOWN!!!

When we let the magic smoke out, we made some sort of mistake. Bottom line is engineering is a lot of hacking and the loss of material must be anticipated. We always need to have a backup plan. Do design well, simulate, breadboard and test, commit to silicon or board and test, and test and test and test. Doing it well is rigorous. For me, after almost 40 years, it's still fun!

Datasheets are your friend! Use a regulator and keep the magic smoke where it belongs....where it can continue to do magic for you!

The folks on this forum are great! Best of fortune to you!

--Bill

-

Bill let's list the project on Indiegogo, "injectable blue smoke" . I'm sure we could raise $100k

-

Now just for fun.....

I had the fortune during my college years of working at the USA's largest steel mill, Inland Steel's Indiana Harbor Works in East Chicago, IN, USA (Inland was the USA's 7'th largest steelmaker at the time and the Harbor Works was the second largest steel mill in the world, I think the largest in Korea). Made a lot of money and was able to graduate from Purdue on time as a result.

In my second Inland stint, between sophmore and junior years, I was an "electrician apprentice". My two bosses, one a degreed EE and the other worked his way up through production, thought (or knew??) I was a wise-ass. So they gave me the task of finding them a 1 Farad capacitor (super caps were still decades from invention). I'm thinking....wow....that's going to be the size of a three bedroom house!! Regardless, I went into their office and started peering though Texas Instruments databooks. Believe it or not I found a part that was a 250,000uF cap. I said lookie here guys, we just wire four of these in parallel and we've got your 1F cap! Their response? No, that can only handle a peak voltage of 12 V. Well....you didn't tell me there was a peak voltage requirement! They knew then I knew they were jerking my chain....but they didn't do it again!

That's not the ultimate magic smoke (UMS) story in my past, but I thought I'd throw it in. The UMS story is in next post.

--Bill

-

Ultimate magic smoke (UMS) story: The summer prior to my senior year in college I was in a salaried position as Student Engineer at Inland Steel in the No.1 Electric Arc Furnace and Billet Caster (a continuous caster). The prior summer, the 1F cap story, worked in the No. 3 Basic Oxygen Furnace and Slab Caster, the number 1 steel making shop in the world, not just then but also now.

Do a web search on continuous casters and find some YouTube videos if you can. They are fascinating....and potentially dangerous as you're about to find out when a 21 year old has control system schematics and a pencil.

The continuous caster control system was in a room perhaps 15m by 10m with most walls covered by enclosed racks of equipment including a bajillion relays. The schematics are a mess, outdated and staff members were concerned about using them and erroneously "fixing" something resulting in a disaster. My job was to red-line the schematics to bring them up to date. So, I have schematics, a pencil, and a multimeter and I'm in the caster control room. There's a door at both ends of the room with the caster, in operation, only about 2 to 3m beyond one of them. I get to work.....with the caster in operation. What could possibly go wrong here?

I'm frustrated, but need to make progress. I think one circuit could be validated if I close this one relay and I'd see just this one other relay flop in an adjacent panel (can anyone guess where this is going?). So I have both panel doors open and find both relays. Using my pencil eraser I close the target relay while keeping an eye on the other.. Then it seemed like there were several hundred relay closures in the room all around me....and it kept on happening!!!! Then a siren alarm sounded....then I looked at the door at the caster end where a red light was flashing.....then I saw molten steel bouncing off of everything.....then I saw two guy run by the door apparently trying to save their lives....then I saw more molten steel fly around all over the place. Oh...my....I just caused a breakout....a phenomenon created when the caster is sped up such that the steel can't form a cooled shell before leaving the mold, so the internal molten contents started spilling onto the floor. Damn! My 21 year old frustration almost got people killed!!!

So, I didn't let the magic smoke out, but I made a very, very big error! There was some water around and some oil & grease, so there was some smoke and a whole bunch of steam. I'll never forget that and it was in 1980!!

Here's the punch line, and it is crazy. After a few weeks I admitted to my boss that I thought I caused the breakout and explained to him in graphic detail. His response to me? "You know what, Bill? We consider you a virgin until you destroy at least $50,000 worth of equipment." Feel free to jump on-line and find one of those inflation calculation tools to see what 1980's $50,000 USD is worth today. You will be stunned!

There's my best magic smoke story, and I was still a student at the time.

take care all!

Bill

-

@crispyoz LOL....really LOL! I am really laughing! You are brilliant!

--Bill

-

@crispyoz I see it's 15 minutes later and I'm still laughing! However one part of my brain asked if this would be $100k USD or $100k AUD.....and that also cracked me up even more!

Anyone else want in? As you can tell by our stories, magic smoke escape is a serious problem. If you're experienced at blowing stuff up you might be just the kind of person we need on the team!

--Bill

-

Ah yes. I have one too! This is from the mid 1960s.

I was studying Electrical Engineering and during one vacation was working at what was called the "Postmaster General's Department" in Australia (they had provided me with a scholarship). In other words, Posts and Telegraphs encompassing communications such as TV, phones and even the ordinary mail.

Anyway, my boss, the Chief Engineer decided to give me some field experience. So I went to a facility high in the mountains. It was a sort of relay station for microwave links between Sydney and Melbourne. Very important as it (as well as TV) carried all telex, phone calls etc between capital cities.The local engineer showed me the various workings, including the triple redundancy with lots of stuff. He proudly opened one rack with multiple power supplies and various transmitters & receivers.

I said "So, if any one of these rack units fails, another one will automatically take its place?" "Yes" he replied.

"Can I try it?"

"Sure".

So I did. I pulled out one of the rack units and all was good.Then I tried to put it back in and somehow got things crooked and pushed way too hard (I was a strong guy).

There was a huge "bang". A huge flash. Sparks flew everywhere.

Then- dead silence. All dead. Everything dead (except the humans)! It was pitch black (no windows in there).After one minute's silence (during which I was seriously considering if I had any future), a couple of dim light bulbs came on. Then all seven bright red phones started ringing. Then a huge (about 100kW) generator started up. Then various lights came on.

I had wiped out everything. But they got telephones, telex and stuff going in about 10mins. But Television took until next day.

That was the end of my work experience in the field. The rest of the time, I was confined to HQ with a drawing board updating diagrams!

Like the molten steel-never forgotten.

Also, I learned something about systems which allegedly can never fail......

Regds,

Dave

-

@David-Kerr OMG!! Definitely one of those things you can never forget, no matter how hard you try! The "...I was confined to HQ with a drawing board..." just made me bust out laughing! We are indeed brethren in causes of industrial disasters!

Television the next day.....OMG!

So, @CAP-33, see what havoc we can create when we're trying to do the right thing? Just imagine if we didn't care...... 8^o

--Bill

-

@CAP-33, you should look at schematic Power Dock 2 expansion shield.

But Omegas take much power and doesn't have power management subsystem. You have to use a big Li-Pol battery or change MCU Like ESP8266 instead.

-

I am running five different Omega2+s off 3.3V 1A SMD regulators. You need to supply brief peaks of current for the WiFi. But the average is less than 300mA. Well within the capability of a LiPo 18650 or a couple in parallel.

I also have two Omega2+ Dashs and they are running just fine off a TO220 LM3940 and are drawing 240mA average at 3.3V.

I have a couple of other Omega2+s running off 12v:3.3v 1A Texas Buck converters. All good. The Omega2+ Dash from the factory uses a 5:3.3 switching regulator rated at 1A when running off USB.So, I see no problem using a single 18650 LiPo through a LM3940 1A LDO regulator. Just add a couple of capacitors per the LM3940 datasheet and I'd also add around 100uF ceramic or tantalum at the input of the Omega2+. There is no point using a switching regulator given the LiPo will be operating between about 3.2 and 4.2V (the latter briefly). Make sure to have LiPo protection either in the cell or in the charging.

Regds,

DaveEdit: Corrected incorrect LM2940 to LM3940

-

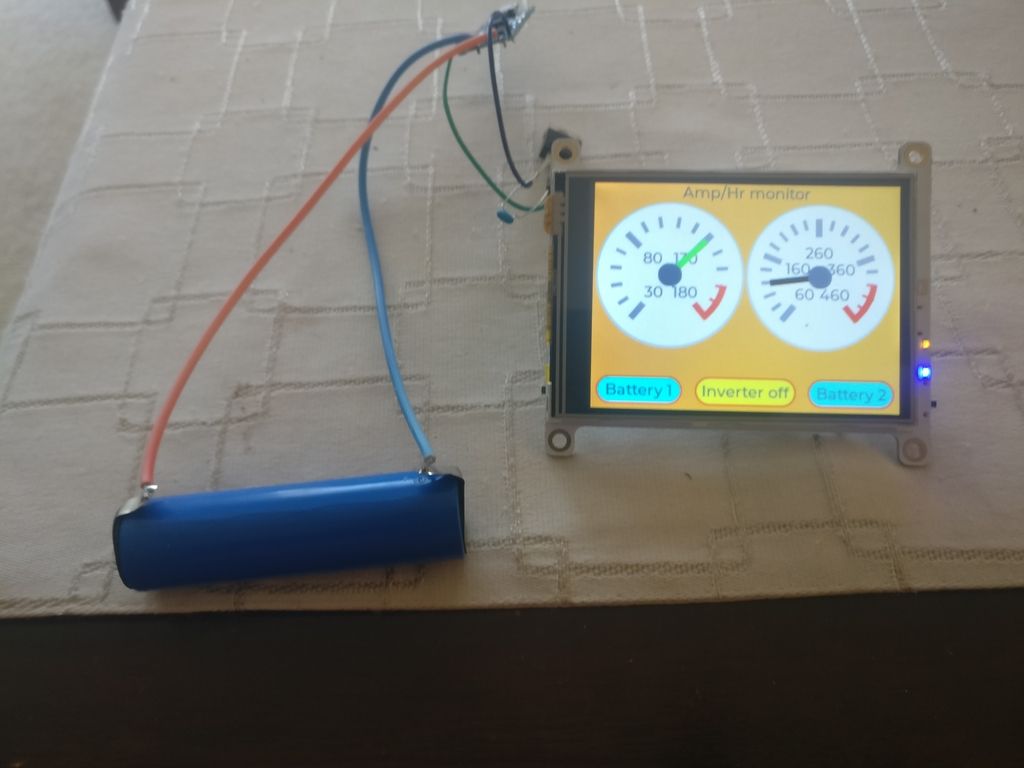

Okay, to illustrate (for anyone wanting to run off a LiPo cell), I quickly knocked up a Lipo with LM3940 regulator. Works fine with the attached Omega2Dash doing WiFi networking over 2 UDP sockets once per second plus running an App I've made with LVGL. Here are some photos.

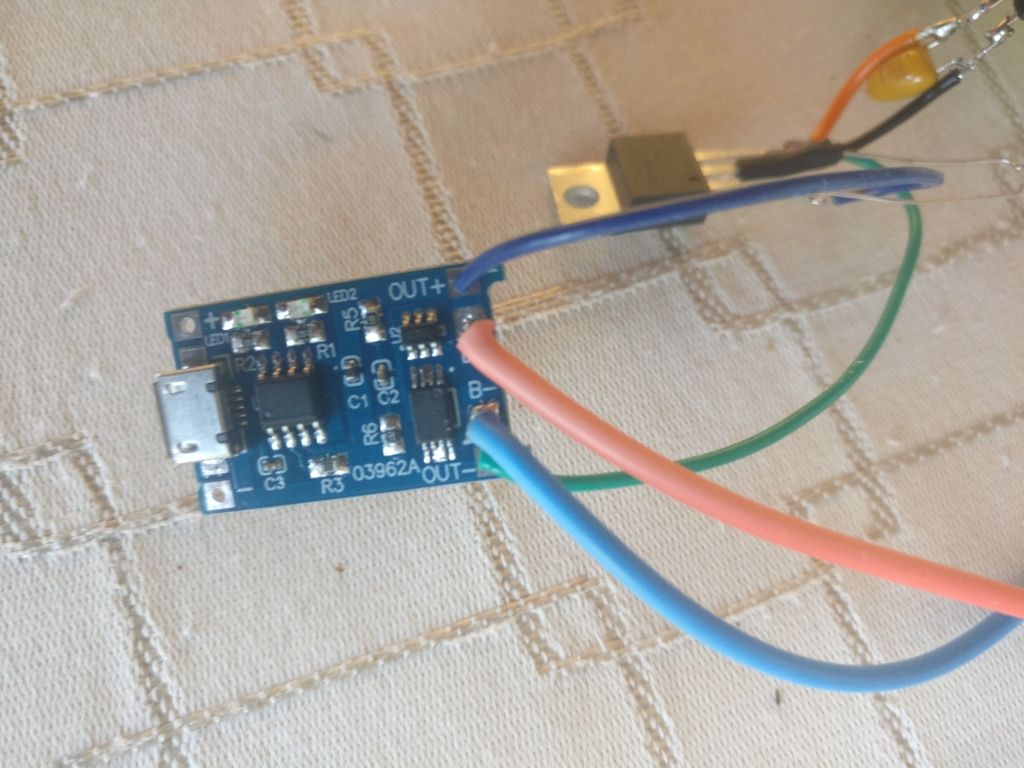

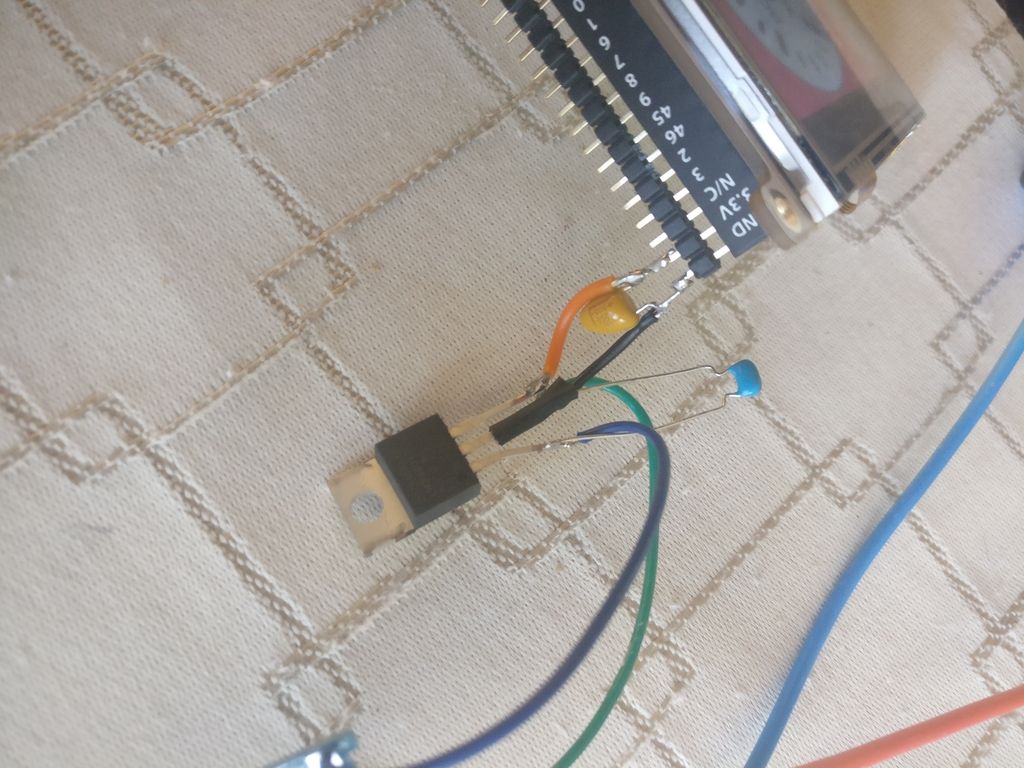

The LM3940 has a 0.47uF ceramic on the input and a 68uF tantalum on the output. In this case, it is driving the Omega2+S plus the Dash display. I have a separate post about connecting to this part of the circuitry (search for 3.3V and 5V and Dash). Cost A$1.80or US$1.00.

The small PCB is a TP4056 based LiPo protection and charger board. Cost A$2.40 or US$1.40.

This cell should run the Omega-Dash for around 10hrs.

Regds,

DaveEdit: Corrected incorrect LM2940 to LM3940

-

@David-Kerr Awesome report!!

--Bill

-

Nice article @David-Kerr thank you !

-

Thanks to everyone for the answers and interesting stories! I solved my problem by applying the DS-DS converter LM2596.