Omega and capacitive touch screen

-

Hi Community,

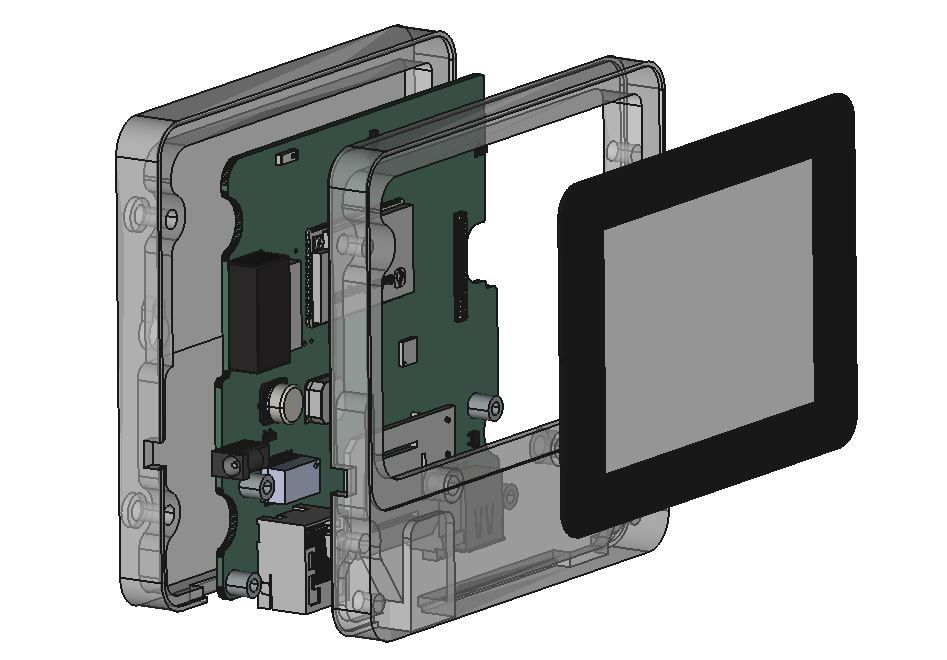

I've been developing a new device embedding an Onion Omega 2S+ with the need of a small (3,5") touch screen. First, I had a look at the Omega Dash (which seems to be the first choice as many functions are already integrated). However, I ran into 2 main issues:

- First: As I'm much more comfortable using Python than C, I had some issues really getting the hang of LVGL.

- Second: The resistive touch screen, didn't really quite fit my requirements regarding "quality". A capacitive touch would be much nicer.

I had a look at several posts from this forum, and noticed many people where looking for touch solutions. However, I didn't find anything regarding capacitive touch....

I therefore went on the hunt of a capacitive touch solution which I could handle with the Omega. Requirements are as follow:

- 3,5" capacitive touch (not resistive)

- Cover Lens Bezel

- Reasonable price

- Drivable with some Python code

After a lot (I really mean a lot) of research, I finally tested a solution from 4D Systems: https://4dsystems.com.au/products/. This Australian company offers quite a lot of different screens and controllers. I finally chose a 3,5" touch screen which can be driven by their diablo 16 controller: https://www.mouser.fr/ProductDetail/4D-Systems/DIABLO16?qs=0lQeLiL1qybL%2FKx9ffo26w%3D%3D

This solution needs quite a bit of custom PCB design, but as my device anyway needs a custom PCB, it wasn't a real hastle integrating the diablo 16 onto the board. The nice thing here is, all the heavy lifting is done by the controller, which directly interfaces with the Omega with a simple serial connection. So once the hardware is done, just get out the Diablo 16 documentation and start writting serial commands....nice.....

Here are my conclusions to this project:

Advantages:

- Super easy to use, once the hardware is integrated. Just write a simple code in the language of your choice (Python in my case) and start talking with the Diablo16 via UART!!!

- 4D Systems offers a free IDE called 4D Workshop enabling a drag and drop style interface in order to design your screen. Again this is super easy and terribly reduces dev time!

- The result is great! The look of the screen and the touch interface are really excellent. The touch response is really fast and gives the user a good experience.

Disadvantages:

- You do need to make a custom hardware. However, I think 4D also offers some intelligent displays directly integrating the controller. This will also require some hardware dev but probably less complexe as directly integrating the controller onto your board.

- All the static data (images, fixed texts, screen layout etc....) is not stored on the controller. The controller accesses this data on an external MicroSD card. This implies two things: You need to integrate this onto your board and you need a high quality industrial grade MicroSD card if you want your product to last.

- As the screen layout is directly written onto the controller and the MicroSD, you cannot perform any remote updates.

- For a final system, you need: Screen + Controller + MicroSD Card + a bunch of other passive components... All this adds up to a certain sum $£€.

Not sure this will meet the requirements for other projects, however for my purposes, this was a great solution enabling a really nice looking device, development simplicity at a reasonable cost. I tried to attach a small video of the screen interaction, this however failed in this post...sorry.

My device as such bundles some other features:

- Ethernet connectivity

- POE (This is really cool as sometimes I need to deploy this device where there is no AC access, and deploying a simple Ethernet cable is wayyyyyy easier than a 220V power line :-))

- 13,56MHz RFID reader (Serial connection with CR95HF controller from ST)

- RTCC chip (MCP7951X from Microchip) with minimum 3 days backup power storage. This is in case power and internet connection would fail simultaneously. The chip is connected to the Omega via SPI.

I'm a little short on time, but I'll try to post some more infos regarding these other features.

Best,

-

@MK That looks very cool, thanks for posting all the details.

-

@MK This is awesome!! Great work!!

I'm curious, you said in Omega and capacitive touch screen:

All the static data (images, fixed texts, screen layout etc....) is not stored on the controller. The controller accesses this data on an external MicroSD card.

This MicroSD card is accessed only by the display controller and not the Omega2S?

-

@crispyoz : Thanks!

-

@Lazar-Demin : Thanks a lot. It took us some time to finalize this dev :-). Correct: The MicroSD only is accessed by the display controller. However, over serial commands from the Omega to the display controller, you can interact with the display itself. I'm pretty fond of this, as just dumping some serial commands really is easy.

I therefore have two MicroSD slots on the board. One is reserved for the display controller and only accessed by it. The second one is connected to the Omega2S+ and serves as memory extension.

If this can be an interesting solution for you, don't hesitate E-mailing me. I'll send you a proto board.

Best,

MK