[RESOLVED] Relays sticking?

-

Hello guys,

I am having some problems with relays sticking. It seems that when the relays are off and they turn on everything is fine. But they will no longer turn off. They need a mild knock on the relay to turn off. Has this happened to anyone?

I am driving some lamps through the relays. About 80watts total @ 120Vac. Is this "normal"?

Should I use a diode on the contacts?

Thanks for any help.

-

Guys, I should note that a good knock on the relay will release the latch. Also I made a mistake. It's 20W total, not 80.

-

Ok, on further testing I have 3 relay expansions that are exactly the same. It seems rather simple enough to use the relay expansion. AC goes IN and OUT in the labeled terminals.

I have 2 more expansions, but I am afraid to use them and "spoil" them as well. Everything seems simple enough, am I missing something?

Do they have to be perfectly "flat", they are leaning slightly to the side (nothing is holding the expansions except the pins themselves).

Could it be a bad batch of relays?

-

@Samuel-Mathieson Not sure what you mean by being flat and leaning slightly to the side. Can you post some photos?

Also, can you try unplugging the load and seeing if the Relays still stick?

It should be safe to test your other Relay Expansions with no load as well.

-

Yes, relays still stick with no load. Checked continuity. If you give them a "knock" on top the relays "unstick".

When I say "leaning" I mean about 5 degrees from flat. I don't think that should affect the relays.

Does the direction matter?

Why does it say "IN" and "OUT" on the relay?

I just bought 10 more from the store, so I will have some extras soon.

-

@Lazar-Demin can you share the exact part number of the relays? I could not find it in the schematic. This thread has my curiosity up on what the exact relay specs are.

-

@Samuel-Mathieson Are you referring to how the Relay Expansion is plugged into the Expansion Dock when you say leaning? If so, that will not affect the relays.

Have you tried your other Relay Expansions with no load?@Jim-Esposito The part number and relay specs are mentioned in the Wiki article on the Relay Expansions.

And the datasheet can be found here.

-

Yes, that's what I am talking about as to how it's leaning. I have 3 relay expansions with no load that stick. They worked before I tried to load them. Can the relays be magnetized somehow with load?

Is IN and OUT important?

I have 3 relay expansion stacked. 2 work well. No problems. The load on those is either none or 120Vac (on one of the two relays). The three that have failed seem to be on 120Vac load.

-

Thanks @Lazar-Demin sorry I missed it

In/Out shouldn't matter at all @Samuel-Mathieson. Is the physical stackup of the extra relay boards affecting how much they are plugged in?

-

@Jim-Esposito What do you mean by the how much they are plugged in?

The thing is the light (relay on/off) light turns on/off as expected, but the relay itself is stuck. The problem is not so much in the software, its in the hardware. The fact that it has happened for 3 expansions then makes me wonder if I got a bad batch.

Do I need to use a diode, or something else on the relay?

-

Your posts are unclear as to how many Relay Expansions you have that work and how many that do not, and in what configuration. When troubleshooting hardware issues, we require photos of your setup as we have outlined in our defective item policy and our forum guide post. Without photos, there is nothing we can do.

As @Jim-Esposito mentioned, IN/OUT do not matter as it is simply an open or closed connection, but they can be useful when examining your circuits to see which wires are going where.

-

I mean physically, how well-seated are the relay expansion modules plugged into the pass-through socket on the expansion dock?

Short of a circuit design problem or defective parts (I am not yet convinced of either, just trying to chime in to help), another area you can turn your attention to, to try to solve the problem, is to see if the stuff is physically making contact for all the signals.

If you have an intermittent connection, something like what you are seeing is possible.

-

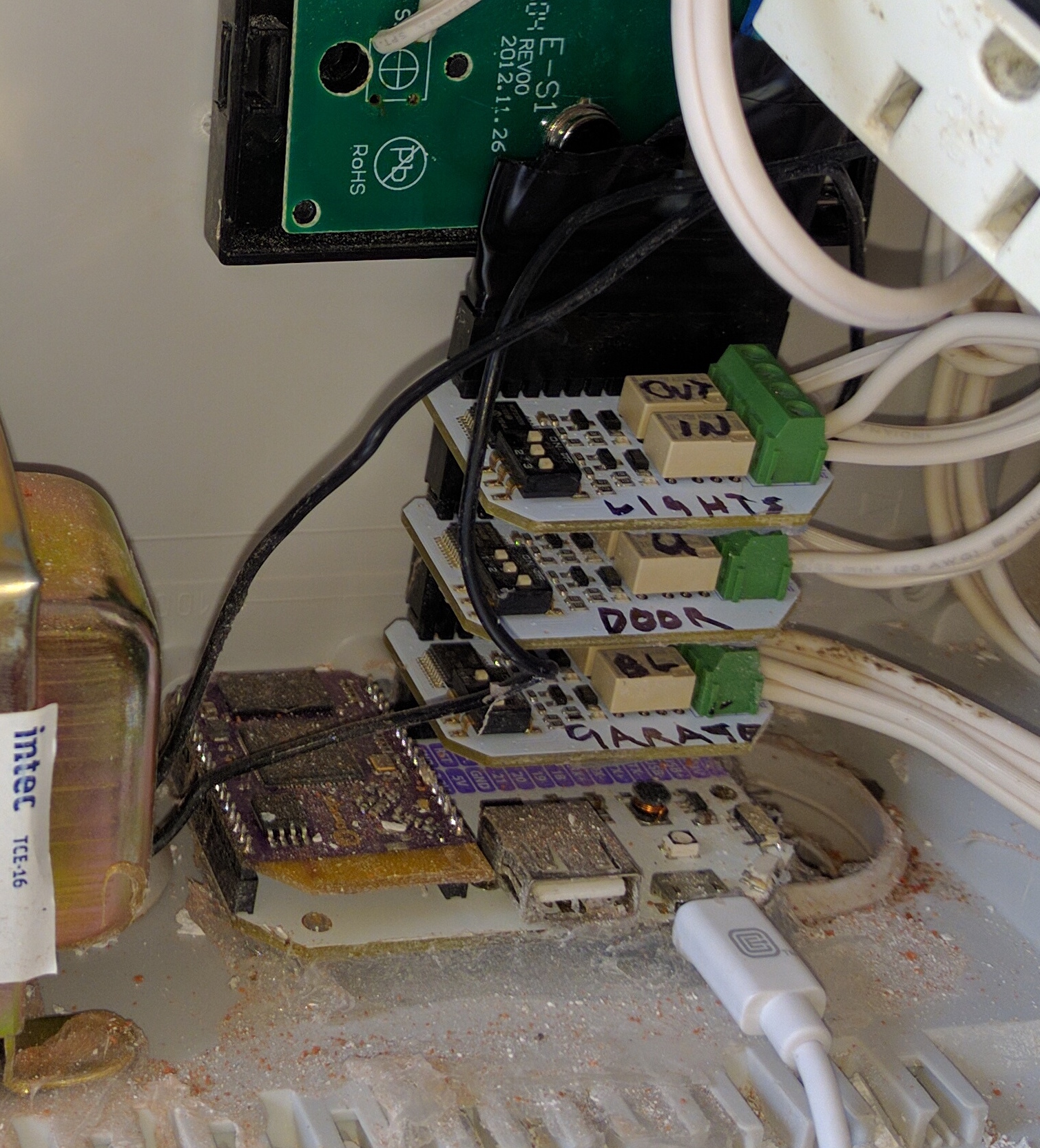

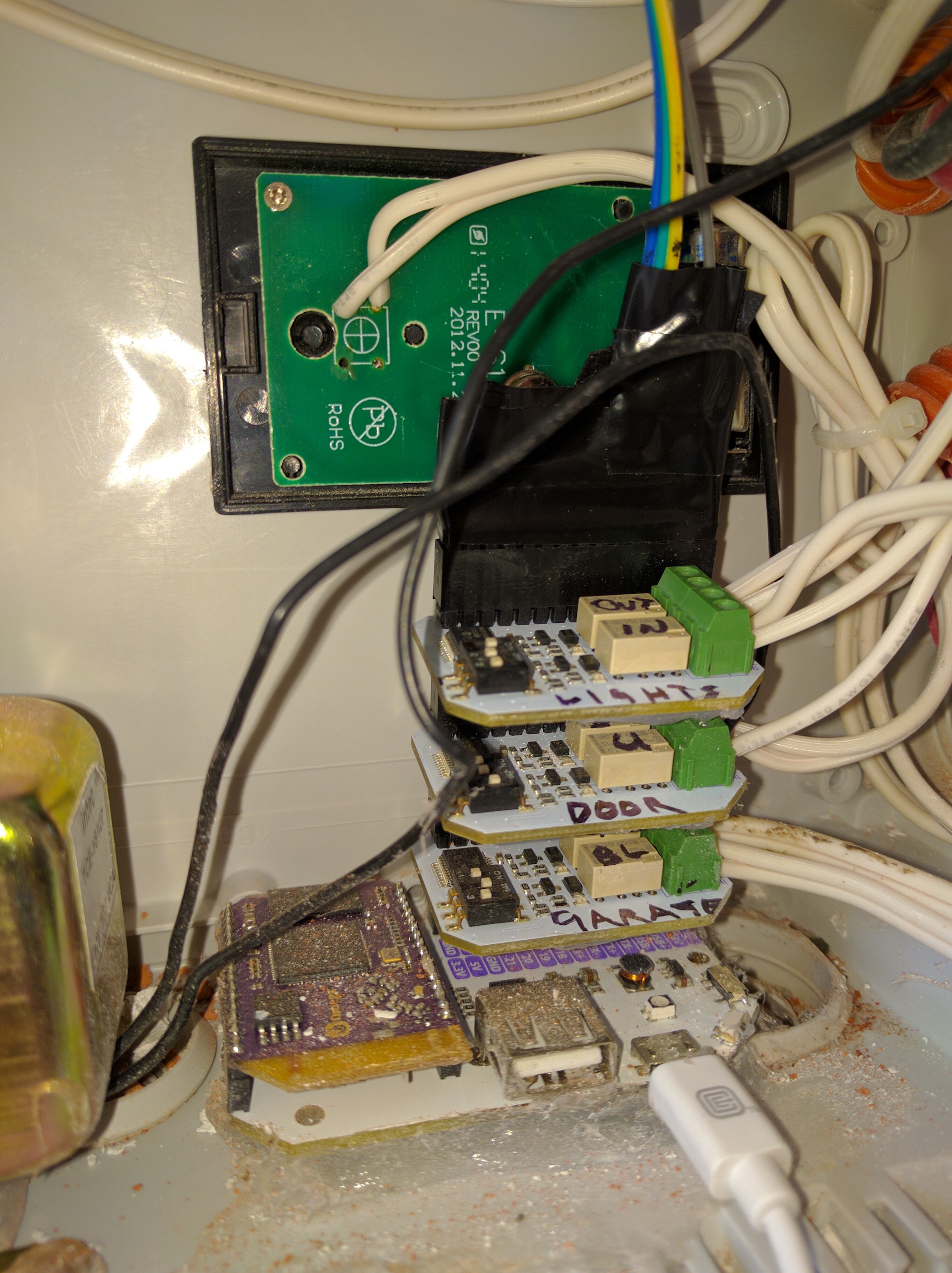

Ok, here is my setup. As you can see, there are 3 expansions stacked one on top of the other.

The problem with the lights expansion occurs no matter if it is on top or on the bottom. Tried 2 others as well. I will try 2 others I have later on tonight and hope that it solves the issue.

-

It is worth noting, that I put silicone on the base of the relay expansions to make sure they would not touch. In reality it was because I was tired of getting shocked when accidentally touching!

-

Okay gotcha.

- If you've already done the trouble-shooting of moving the expansions around and they still stick, I think that rules out the possibilities I suggested.

- I don't think this is the cause of any of your troubles, but for this installation you may want to consider printing out a 3D case for the Omega and dock, at least to keep some of the stuff from getting dust and dirt on them. I don't have the link handy, but I did get one of the cases I found online printed recently, and the fit was near-perfect first shot. I wound up not needing the top portion, but if I did it would've needed just a bit of tweaking to allow the relay expansion to sit nicely.

-

Jim,

Thanks. The dust will be removed. The case is a plastic case I bought specifically for storing the omega and the other bits and bobs. I used silicone to stick the Omega to the plastic case. Either way. Thats 3 relays that don't work. I wonder if perhaps I got a bad batch. I bought another 10 today so I hope that these will not have problems. I will test with another 2 relay expansions I have today. See what happens.

-

The most common cause of relays sticking is because of micro-welding of the contacts caused by arcing when the contacts close/open.

This can occur even when the current being switched is within the rating of the relay.

This micro-welding can usually be broken by suitable mechanical shock - i.e. giving them a knock

When the circuit being driven is subject to an increased current surge on making contact - e.g. when switching an incandescent bulb, the initial cold current can be significantly greater than the normal operating warm currentNormal suggestions to minimise this micro-welding are:

- Try driving the relay with a higher current so the relay operates faster closes faster to reduce possible arcing time - though I don't see how this could be done with the Relay Expansion

- Use a relay with a stronger return spring so it opens faster to again reduce arcing time - again not possible on the Relay Expansion without physically replacing the relays

- Use some suppression across the contacts to reduce the arcing - e.g. connect a capacitor across the contacts (i.e. from the In to OUT connections) - I am not enough of an electrical engineer to suggest a suitable value for the capacitor but it should have a voltage rating high enough for the circuit being switched and if switching AC it should NOT be an electrolytic capacitor.

Finally, if the problem really is being caused by the relays on the Relay Expansion not being rated highly enough for the circuit being switched, you could use the Relay Expansion relays to switch separate external relays that have a higher rating

-

@Kit-Bishop Kit,

They all seem to work again after "giving them a knock".

I will read a little on the capacitors to see if I can find a suitable value as I know very little of the matter as well!

Thanks for the suggestion.

-

Ok, I had a chat with my father, who is an old engineer and used to work in BT in the 50's, he told me of a trick they had back then. Apparently they let the relay weld and would "unstick" it, and do this a few times. He claims this would even out the surface and create a bigger surface of contact so less micro-welding.

Odd no?

Well, I tried this, and after 5 or 6 times the relays no longer locked!

All is well now

Thanks guys.

-

@Samuel-Mathieson said in Relays sticking?:

...Apparently they let the relay weld and would "unstick" it, and do this a few times...

I'm not sure if I understood right, you took the solder Iron and made the 8legs of the relays "warm" that the solder ran back to the hole of the circuit board from the extension? Without adding new solder?

-

No, he let the relay stick a few times and it worked itself out. Interesting!

Glad you're on your way. BTW, not sure your level of solder skills, but I like two of the suggestions above and would try either of them if you get more problems:

- Replace the relay with a pin-compatible heavier-duty one (or)

- Have the onboard relays drive the coil of heavier-duty relays